Synchronised movement enhances performance of telescopic rail system

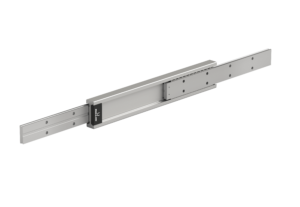

BMG has introduced the new Rollon HGT-MG telescopic rail with synchronisation magnets for smoother, more controlled, higher-capacity extension.

Rollon has expanded its HGT heavy-duty telescopic rail range, with the launch of the new HGT-MG, a design that incorporates a refined ball-cage geometry and internally mounted synchronisation magnets to improve operational efficiency and extend service life. The new series is designed to reduce the force required to open the rail, aligning its elements during extension, to provide controlled, repeatable movement under load.

The HGT design uses a robust double T-shaped intermediate element paired with two corresponding sliders to withstand challenging operating conditions. The addition of synchronisation magnets in the HGT-MG series provides enhanced smoothness, controllability and durability, without altering the established mounting footprint of the HGT range.

“Rollon’s HGT heavy-duty telescopic rail range ensures simplified motion, while improving fatigue resistance. The synchronisation magnets align and synchronise the elements during extension, which reduces operating effort and ensures higher load capacity,” explains Leon Koekemoer, BMG’s Linearway & Ball Screw Product Specialist. “This new design also helps extend service life because the system experiences less mechanical impact during repetitive cycles.”

The HGT series forms part of Rollon’s fully extending, heavy-duty telescopic rail range, which is used extensively in construction and machinery applications, as well as in automotive and rail-vehicle systems. All rails and sliders in the series are manufactured in steel and finished with zinc electroplating and thick-film passivation to meet REACH and RoHS requirements. A Stainless-Steel version is also available for environments requiring additional corrosion resistance.

Through BMG’s partnership with Rollon – specialists in the production and development of linear motion systems – the BMG team is able to supply and support advanced linear motion systems, to meet growing demand in Africa for precision in industrial automation, ensuring sustainable production.

BMG’s Rollon portfolio includes linear guides, telescopic rails, actuators and multi-axis systems, as well as ball screws and rotational units – engineered to function reliably in heavy-duty industrial operations. These robust components withstand high loads, continuous use and exposure to harsh environments, making them suitable for sectors including automotive assembly, electronics manufacturing, packaging and materials handling.