Multi-directional forklift technology ensures space saving in warehousing

Shamrock Handling Concepts offers innovative warehouse planning solutions, through advanced multi-directional forklift technology that can double storage capacity, without the need for costly building expansions.

“As warehousing costs continue to rise and available space becomes increasingly scarce, we are demonstrating to customers that the solution to their storage challenges may not require constructing new facilities,” explains Kobus Cronje, General Manager, Shamrock Handling Concepts. “Multi-directional forklifts are revolutionising how warehouses operate, by combining the capabilities of three separate machines into one versatile unit. Our Combilift C-series multi-directional forklifts represents a fundamental shift in how businesses are approaching warehouse planning.

“Rather than immediately considering costly building expansions, companies can now maximise their existing footprint through the investment in smarter materials handling equipment. We’re assisting our customers achieve double their storage capacity simply by adopting multi-directional forklift technology.”

Shamrock Handling Concepts offers a warehouse planning service to customers that includes comprehensive site surveys and detailed visualisations that illustrate how multi-directional technology transforms existing storage facilities.

Our Combilift machines integrate the functions of a side-loader, counterbalance and narrow aisle forklift into a single machine. Advanced technology enables operators to change the direction of travel by 90 degrees at the flick of a switch, allowing even the longest loads to navigate easily down narrow aisles, through standard doorways and around obstacles.

The engineering behind multi-directional forklifts allows racking to be placed significantly closer together, maximising facility space, whilst reducing the amount of operational area required. This efficient design minimises operating costs and eliminates the expense and disruption of warehouse expansions.

Multi-directional forklifts offer customisable configurations to suit specific operational requirements, whether handling timber, steel, building materials or other long products. The flexible machines combine counterbalance capabilities with sideloading functionality and narrow aisle performance, creating a versatile solution that adapts to diverse warehouse environments.

As businesses face mounting pressure to improve efficiency whilst controlling costs, the multi-directional forklift offers an efficient alternative to traditional warehouse expansion. By rethinking how space is utilised and selecting material handling equipment that maximises storage density, companies can achieve substantial improvements in capacity and operational flow. The ability to handle materials with greater precision also contributes to decreased product damage and minimal waste.

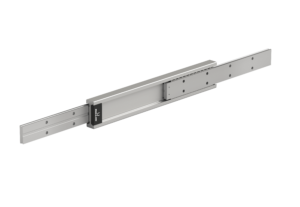

Multi-directional Combilift C-series forklifts

Shamrock’s Combilift C-series forklifts, with a loading capacity of 2 500 – 25 000 kg, are designed to travel forwards, sideways and diagonally. These versatile machines have a low centre of gravity and an integrated platform that provides a stable base on which to rest long loads, like planks, ceiling boards, steel, pipes and tubes during transport. Unlike conventional forklifts, there is no need to carry the load at elevated levels, which significantly improves safety, load stability and control.

The compact chassis and multi-directional movement enable operation in tighter spaces than conventional counterbalance forklifts allow. This design helps businesses make better use of available warehouse space, without the need for structural modifications.

Standard features of this range include a rubber mounted cabin, load-sensing steering, a 4-way lever positioning of wheels and 3-wheel hydrostatic drive.

The cab is mounted to the side of the mast, giving the operator clear visibility of the surroundings, forks and load. This is important when handling high-value or easily damaged materials. The moving mast system and the option of a hydraulic forklift positioner allows the operator to adjust the forks, reach out and lift and place the load, without having to leave the cab.

Power is transmitted through a hydrostatic drive rather than a mechanical gearbox. The advantage of this design is smooth, controlled operation with no gear changes, which improves manoeuvrability and enhances operator comfort. The advanced ergonomic cab layout has been designed for improved operator comfort which is important in operations with long shifts.

Another benefit is suitability for use on different surfaces indoors and outdoors, which reduces the need for multiple equipment types. A single machine can be used to safely move materials between outdoor storage and indoor processing facilities, or around yards, loading areas and warehouses, in all weather conditions.

Apart from Combilift multi-directional forklifts, Shamrock Handling Concepts also supplies and supports Moffett truck-mounted forklifts, Agrimac all-terrain and off-road forklifts and BUNDU rough-terrain machines.